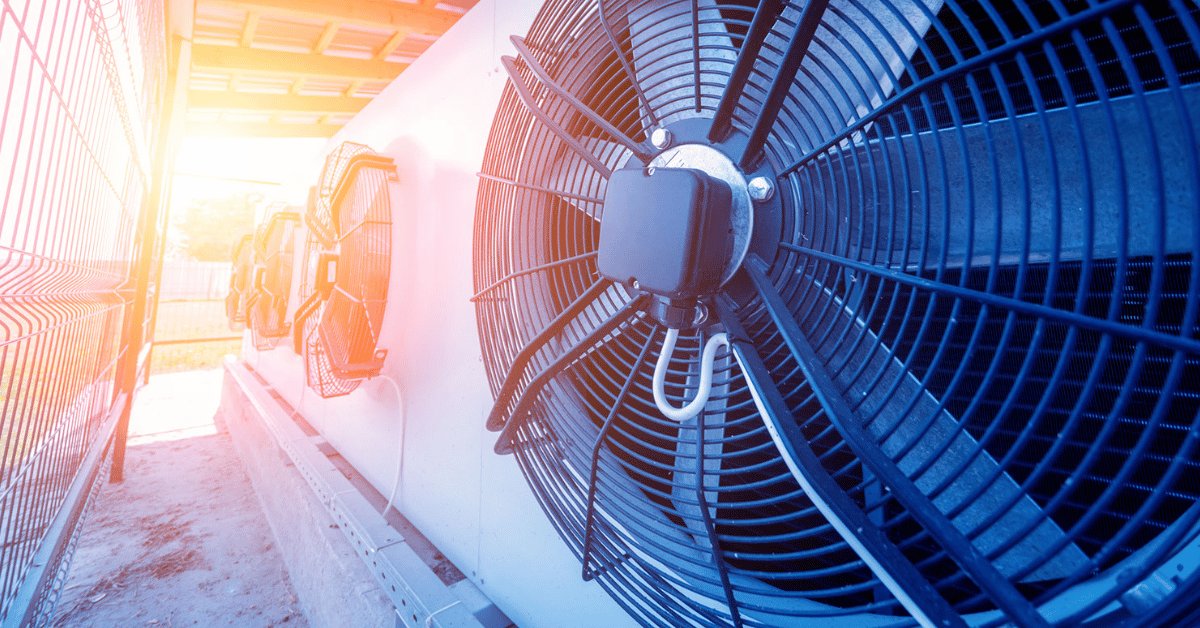

Simple, Scalable IoT Connectivity Options for Smart Air Vents

Supply your smart HVAC control system with remote connectivity and significantly reduced latency. With the Nabto platform, customers can have direct communication with their HVAC system without intermediaries. Nabto Edge allows customers to remotely control smart HVAC vents from anywhere through an end-to-end encrypted connection.